Virtual Testing

The Engineering design process is the conversion of material into useful product. The need for both simulation and experiments for reliable and rapid development of new products is complimentary. ATOA offers simulation based engineered product development and testing for the first time right product development. The interplay between simulation and testing are highlighted to showcase the importance of Virtual Testing to develop Virtual Innovative Products for unique customer experience with highest performance and reliability at lowest cost .

Simulation based Engineering Design and Testing, provides unparalleled access to real-world conditions and is credited with numerous success stories. CAE Simulations can be used to predict unknown product performance for first time right product development and to predict the future outcome and what if scenarios.

Virtual Testing Simulations has none of the following limitations of experimental designs tests, such us, material Cost constraints, harsh/unrealistic parameter ranges, and Environment, Health and Safety concerns.

Simulation and Testing are complementary for Testing of Materials, Similar to Theory vs Experiments. Testing are generally used to verify simulations. Simulation also includes virtual material testing for Faster and cheaper new product Development, Prediction of anisotropic, complex, costly and time consuming experimental properties, Simulation helps to cut the cost and time .But Final, limited Testing is a must for new product Development and Introduction into the Market.

Testing is part of the engineering Process. We do testing, To Avoid Premature Failure, To augment Computational Simulation based Engineering for Virtual product development and To provide inputs to simulation and final Validation and Verification. Virtual testing of Material, product, process, system development for Part performance prediction and Quality control/assurance, Long term reliability.

Typical Material Properties and experimental Tests.

Mechanical: Strength, stiffness, elasticity, plasticity, ductility, brittleness, hardness, wear resistance, Impact strength, fatigue life.

Thermal: Expansion, specific heat, thermal conductivity, Thermal diffusivity

Electrical & magnetic: Conductivity, permeability, permittivity, dielectric properties.

Acoustical: Sound transmission, Attenuation.

Optical: light transmission/reflection, haze, absorption, Color.

Computer Aided Virtual Testing Simulation.

Simulation to predict the experimental properties of systems. For example, It is difficult to characterize the anisotropic properties of composites. Numerical models is used to predict the complementary anisotropic properties.

Simulation to mimic the testing is performed to zoom into the inner working mechanism of materials and products.

The progressive growth, failure, damage mechanics can help to reverse engineer the materials for improved and optimal performance.

Virtual Testing are used to simulate and predict high risk and costly experimental tests for cost effective product development.

Virtual Testing is also used to predict the emergent property of matial sytesm.

Virtual Testing is used to predict the composites, nano, smart and metamaterial.

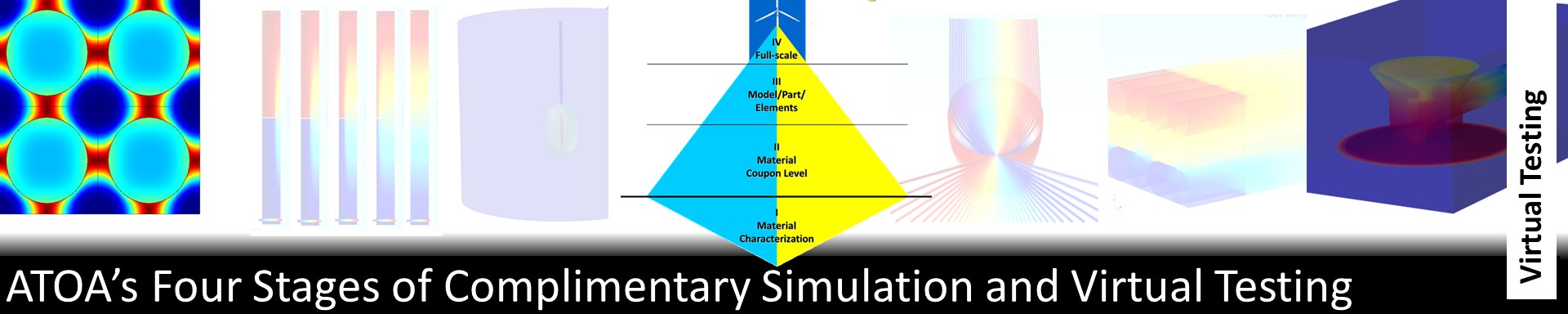

ATOA offers Virtual Testing services at Four Stages,

Level 1: Material constituent, material characterisation level,

Level 2: Material coupen level, material property level,

Level 3: Part levet , part performance prediction level,

Level4: Full scale level, system level performance prediction level.

We simulate in a virtual environment, as per ASTM, ISO and other relevant testing standards. We routinely do the following virtual test.

- Mechanical property (e.g, Modulus,...)

- Thermal conductivity, CTE

- Dielectric constant

- Thermal U value, R value

- Acoustics STL, Rw

- Optical. Light transmission, reflection, absorption…

- Solar Light transmission, reflection, absorption,

- Photo elastic Coupled stress-optical

ATOA offers multiphysics Simulation and virtual Testing for the Engineering Design of First Time Right Product Development .